We have over 25 years of experience in die cutting— Whether you require thousands of parts or just a few we can be your cost effective provider.

Commonly Used Material

- Sheet Rubber

- Conveyor Belting

- Fabric

- PVC

- Urethane

- Pure Gum Rubber

OEM Equipment Parts – Made to requirements—could include:

- Skirtings

- Flashings

- Gaskets

- Flaps

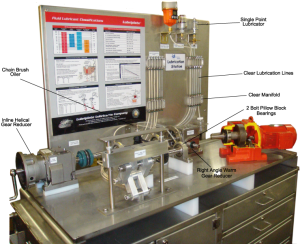

Training Station

Displayed is a customized Lubrication Station. This station is built on a stainless steel frame with heavy duty casters. The station includes:

- SEW Eurodrive Inline Helical Reducer Cutaway

- Baldor/Dodge Quantis Inline Helical Gear Reducer

- Baldor/Dodge 2-Bolt Pillow Block Bearings

- Baldor/Dodge Tigear-2 Right Angle Worm Gear Reducer

- Single Point Lubricator

- Chain Brush Oiler

- Visual Lubrication Manifolds and Lubrication Lines

- Machine Specific Application Lubrication Demonstration

- Lubriplate Reference Chart for Lubricants

Also displayed is a clear acrylic gear box – created for visual inspection of the gearing lubrication inside a standard gearbox, and the cut-aways of the Baldor/Dodge bearings and the SEW Eurodrive Reducer.

This display is just one of any number of variations on a training station.

For further information, please feel free to give us a call 800.952.5072 or send us an email sales@int-dist.com.

INDUSTRIES SERVED

- Automotive

- Bottling & Beverage

- Dewatering Systems

- Food Processing

- Foundry

- Furniture Industry

- HVAC

- Life Sciences

- Wood Processing

MECHANICAL ENGINEERING

Initial Engineering

- Feasibility Studies

- Cost Analysis

Detailed Engineering

- Component Selection

- Sub Assembly

- Integration

Detailed Drawings

- Manufacturing Drawings

- Work Instructions

CASE STUDIES

- Lean Cell Retrofit

- Automotive Brake Rotor Balancing System

- Automated Glue Dispensing Cell

- Automated Yogurt Press

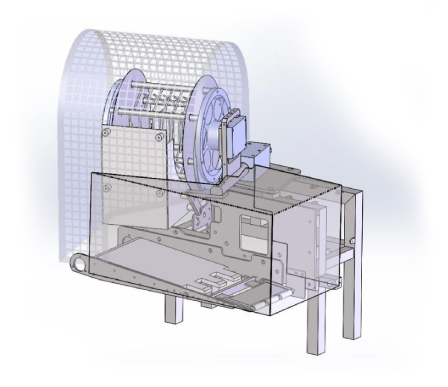

Lean Cell Retrofit

- Scope: Reverse engineer and design retrofit of 30 existing lean cells

- Purpose: Retrofit of leans cells to standardize across the production line

- Drives: Lesson Motor, KEB drive clutch

- Controls: Allen-Bradley Controllogix

- Rate: Up to 1000 units an hour

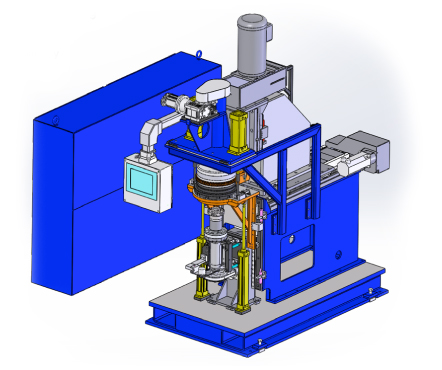

Automotive Brake Rotor Balancing System

- Scope: Design and spec testing balance unit for automotive brake rotors for US based automotive company

- Purpose: Testing and correction of imbalance of brake rotors coming from production line

- Drives: Allen-Bradley Servos

- Controls: Allen-Bradley Controllogix Rate: Up to 45 units an hour

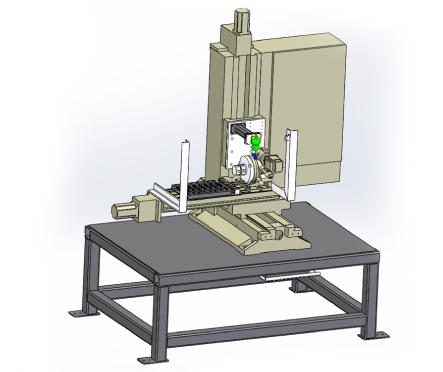

Automated Glue Dispensing System

Automated Glue Dispensing System

- Scope: Design, spec, build, and install automated glue dispensing system for German based company

- Purpose: The dispensing of two part epoxy in precise locations on plastic glides in 3 and 4-axis

- Drives: Leadshine drivers

- Controls: LinuxCNC

- Rate: Up to 100 units an hour

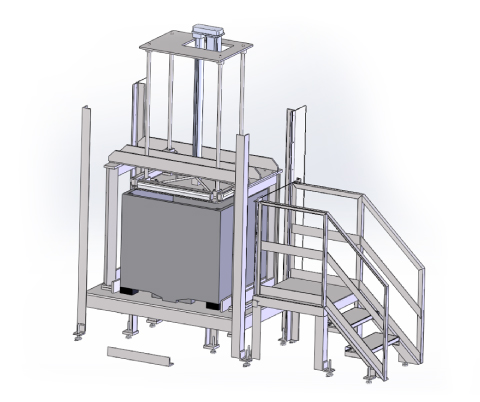

Automated Yogurt Press

Automated Yogurt Press

- Scope: Design, spec, build, and install automated yogurt press for Swiss based company

- Purpose: The metered dispensing of yogurt from bulk storage containers to production line

- Drives: Allen-Bradley Servo

- Controls: Allen-Bradley CompactLogix

- Rate: Up to 3000 lbs. an hour

FIELDS OF EXPERTISE

HYDRAULICS PNEUMATICS FEA POWER TRANSMISION